Nano Solar Heat Reflective Paint for Metal Surfaces

Add time:2021-12-06 View counts:

Nano Solar Heat Reflective Paint for Metal Surfaces

Jiajialy Nano Solar Heat Reflective Paint for Metal Surfaces is produced with resin, high-performance surface nano treated hollow glass beads, and self-developed nano slurry, etc in according with special production process.

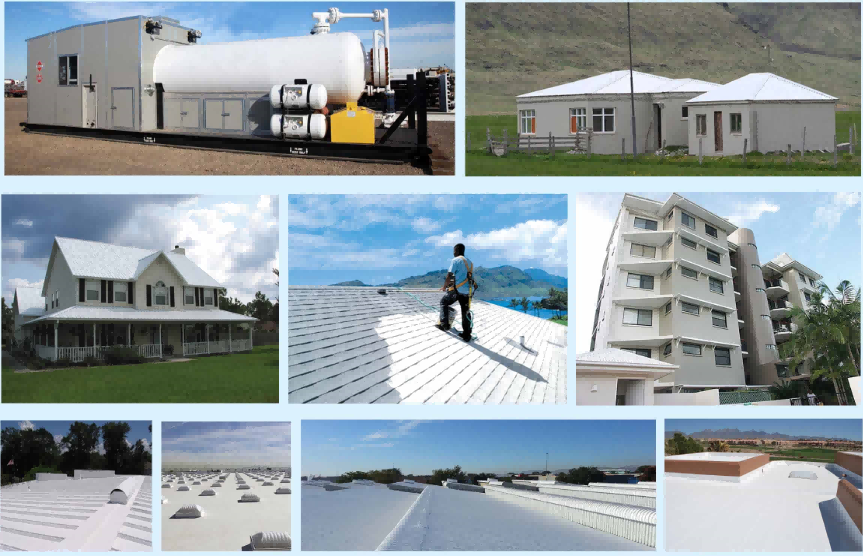

It can be widely used on all kinds of water or oil tanks, pipelines, vehicles, ships, oil petrol chemical industry, roof and wall of buildings. By reflecting solar radiation. It can reduce surface temperature from 15-30℃ and besides it exhibits strong lasting reflectivity, simple application( roller, brush or spray), weathering resistance and contamination resistance.

Product Parameters

| No. | Test Items | Requirements of Standard | Test results | Individual conclusion | |

| 1 | Condition in container | No agglomeration, uniformity after stirring | No agglomeration, uniformity after stirring | Passed | |

| 2 | Application property | No difficulty in brushing for the second times | No difficulty in ;brushing for the second times | Passed | |

| 3 | Film appearance | Normal | Normal | Passed | |

| 4 | Dry time(tack-free time) | ≤2h | 50 min | Passed | |

| 5 | Alkali resistance | 48h, no changes | 48h, no changes | Passed | |

| 6 | Water resistance | 96h, no changes | 96h, no changes | Passed | |

| 7 | Stability of low temperature storage | No lumps, gel and separation | No lumps, geland separation | Passed | |

| 8 | Temperature change resistance | No change | No change | Passed | |

| 9 | Scrub resistance | ≥2000 times | 2000times, no grinning effect | Passed | |

| 10 | Dirt pickup resistance | ≤20% | 17.8% | Passed | |

| 11 | Solar reflectance (white) | ≥0.83 | 0.86 | Passed | |

| 12 | Hemispherical emittance | ≥0.85 | 0.88 | Passed | |

| 13 | Tensile strength | ≥ 1.0 MPa | 1.3 MPa | Passed | |

| 14 | Elongation break | ≥ 100% | 317% | Passed | |

| 15 | Artificial weathering resistance (400h) | Appearance change | No change | No change | Passed |

| Chalking | ≤ 1rank | 1rank | Passed | ||

| Color change | ≤ 2rank | 1rank | Passed | ||

| Solar reflectance (white) | ≥ 0.81 | 0.86 | Passed | ||

| Hemispherical emissivity | ≥ 0.83 | 0.86 | Passed | ||

| 16 | Waterproofing (0.3MPa,30 min) | Impermeable to water | Impermeable to water | Passed | |

| 17 | Water vapor transmission | ≥ 8.0×10-8g/(m2·s·Pa) | 10.7×10-8g/(m2·s·Pa) | Passed | |

Application Areas

1. Stucco and masonry parapet walls

2. Cement concrete surface

3. Stone surfaces

4. Roof and exterior wall of theaters, stadiums, large conference and exhibition center and residential buildings.

Application

Substrate material requirements

1.New concrete or cement-sand mixed wall surface has to be well dried(14days in summer and over 20 ays in winter) with moisture content ≤10% and PH value ≤10 before application.

2. Substrate surface should be smooth, strong without crack, peeling off, surface dusting, oil etc

Preparations

1. Mix well in the bottle before application.

2. Normally original viscosity is ready for application, if too thick, 5% water to be added for dilution.

3. Application is not allowed in rainy or storm weather, protection is needed in coming 12 hrs after application to prevent coating from washing off; the wet wall surface after rain should be dry before application.

4. Application has to be stopped if temperature less than 5℃ and humidity ≥80%; application is prohibited if temperature≤0℃

Application method

1. Application can be made by roller, brush or sprayer.

2. First undercoat(Alkali resistant seal coat for building; Anti corrosive seal coat for metal) is necessary for substrate that never treated,

3. Then solar reflective coating to be coated at least twice with gap ≥4hrs to maintain its thickness at 200-300μm after dry

4. In case of summer peak with high temperature and less humidity, surface should be wetted with water, and do the application after water is absorbed, otherwise properly cause peel off or cracking problems

5. Do trial test on small area is necessary before large scale application due to the different conditions in different area and substrate.

Storage and transportation

1. Keep in dry, cool indoor place (0℃~40℃)with good ventilation.

2. Keep off direct sun and rain; collision and upside down should be avoided during transportation.

3. Shelf life: 1 year; inspection is necessary for using after validity.